Open-Pit Mine

Khan Altai Deposit

Located at an elevation of 2,600 meters above sea level, it is currently the highest-altitude open-pit mine operating in Mongolia.

Mine Introduction

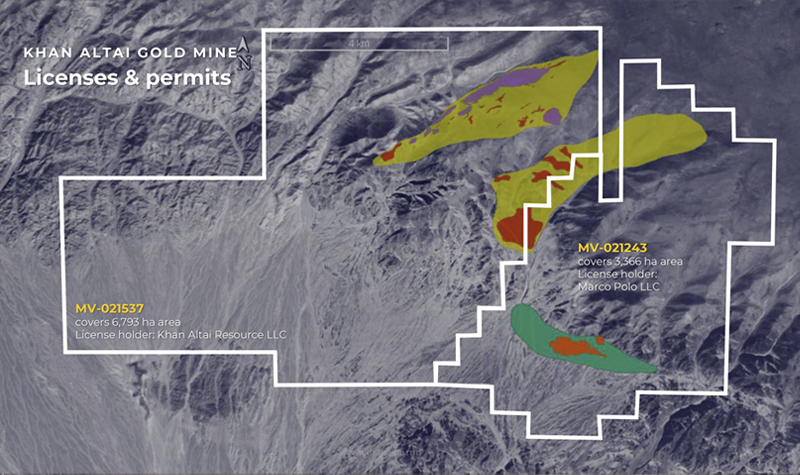

The mining site of Khan Altai Resource LLC is located in Naran bagh of Yesönbulag soum, Govi-Altai Province, approximately 1,000 km from Ulaanbaatar and 100 km from the provincial center. According to an internationally compliant JORC resource report, the deposit contains an estimated 86.73 tonnes of gold.

National company

“Khan Altai Resource” LLC is a national company that actively implements advanced technologies and innovation in the mining sector, applying the principles of sustainable development by ensuring a balance between environmental, social, and economic factors. All of the company’s operations are carried out entirely based on the knowledge, skills, and experience of Mongolian engineers and professionals.

Phase I operation

In the first phase of the project, a processing plant with an annual capacity of 3 million tonnes of oxidized ore was constructed, with construction works, equipment installation, and all required engineering infrastructure implemented as an integrated комплекс.

With the commissioning of this plant, mining operations commenced on a stable basis, enabling efficient ore processing and successfully laying the foundation for the future development of a primary ore processing facility.

Phase II operation

In the second phase of the project, a processing plant will be constructed to treat 5 million tonnes per year of primary ore using flotation, oxidation, and CIL technologies, with environmentally friendly and advanced technologies introduced in stages. As part of this phase, a 6.3-km energy-generating conveyor system and stationary crushing plants are being commissioned.

Once the plant is fully operational, the mine’s overall capacity will increase, ensuring stable and long-term mining and production operations, while creating tangible conditions for a significant improvement in production efficiency and output.

Khan Altai Resource

General Site Plan of the Mining Area

Exploration Drilling and Geological Studies

Between 2018 and 2024, a total of 189,000 meters of exploration drilling and geological studies were completed to define and expand the resources of the Khan Altai deposit.

Layered Tailings Storage Facility

A multi-layered tailings storage facility has been constructed and commissioned in compliance with international environmental standards.

4G LTE Communication Network

A 4G LTE communication tower covering the entire mine and camp area was constructed, providing high-speed data and reliable voice connectivity.

Ore Haulage Technology Road

An 8.5 km heavy-duty technological road was commissioned to transport ore from the open pit to the processing plant.

Substation and Diesel Power Generation

Substations and diesel generator stations were constructed to provide both primary and backup power supply for the mine.

Fuel Distribution Station

The first fuel distribution station was built and commissioned to ensure an uninterrupted fuel supply for mining equipment and machinery.

35 kV Overhead Power Transmission Line

A 10.8 km long 35 kV overhead power transmission line was constructed and commissioned, connecting the project to the integrated national power grid.

Ore Processing Plant

As part of Phase I of the project, an ore processing plant with an annual capacity of 3 million tonnes was successfully constructed.

Water Supply System

A centralized water supply system for both potable and industrial use was established, along with water reservoirs for fire protection and emergency purposes.

Greenhouse Facility

Within the framework of the greening program, a greenhouse for cultivating seedlings and supplying trees and plants to the mine site and surrounding region was commissioned.

Wastewater Treatment Plant

A modern wastewater treatment facility was commissioned to treat domestic wastewater generated from the mine and camp areas in accordance with current standards.

Employee Accommodation

Modern and comfortable accommodation facilities for 460 employees, along with recreational and leisure areas, were commissioned.

Dining Hall

A fully equipped kitchen and a comfortable dining hall were commissioned to serve employees working at the mine site.

MMD Stationary Crusher

A stationary MMD crushing plant from the United Kingdom, with a capacity of 4 million tonnes of ore per year, was constructed.

Maintenance Center and Warehouse

A central warehouse for spare parts and materials, along with a heavy equipment maintenance and service center, was commissioned.

Processing Plant Laboratory

A modern laboratory was established to conduct quality control and metallurgical testing for the processing plant.

Office Complex

A multifunctional building integrating administrative offices, training facilities, a medical clinic, and a fitness center was commissioned.

Conveyor System

A 6.3 km long conveyor system with a capacity of 1,150 tonnes per hour was commissioned to transport ore from the open pit to the processing plant.

Employee Accommodation

To further improve living conditions and comfort for employees, construction has commenced on accommodation facilities with a capacity for 240 people, including a sauna and swimming pool.

Sports Hall, Lounge, and Outdoor Facilities

A sports hall, lounge/bar, and various outdoor sports facilities are being constructed to support employees’ recreation and leisure activities.

1,000-Tonne Fuel Storage Capacity

Fuel storage capacity has been increased to 1,000 tonnes, ensuring continuous and reliable operation of mining equipment and power generation facilities.

Mine Location

The mining site of Khan Altai Resource is located in Naran bagh, Yesönbulag soum, Govi-Altai Province, situated approximately 1,000 km from Ulaanbaatar and 100 km from the provincial center.